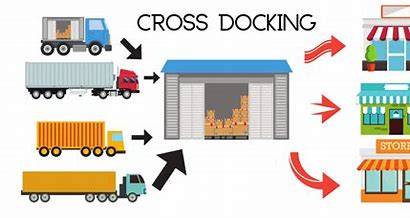

Cross docking is a way of moving products directly from a supplier or factory to a customer or store without storing them in a warehouse. It happens in a special place with doors for trucks to enter and go out quickly. The products are received through one door and then sent out through another door right away.

What is Cross-docking Understanding the concept & definition?

Cross docking is a logistics process in which products or goods from a supplier are unloaded from incoming trucks, sorted, and then directly reloaded onto outbound trucks for delivery to customers, without being stored in a warehouse or distribution center. In other words, cross-docking is a type of supply chain management that involves the transfer of goods from one truck to another, with little or no storage time in between.

The concept of cross docking is to minimize the time that products spend in the supply chain, which reduces inventory holding costs, labor costs, and the risk of damage or obsolescence. This process is used in industries such as retail, grocery, and manufacturing, where speed and efficiency are critical. Cross docking is also used for perishable goods or products with a short shelf life.

Also, it’s important to know how to optimize the warehouse layout

Types of cross-docking

- Pre-planned cross docking: This involves pre-planning the process to ensure that inbound products are matched with outbound orders before they arrive at the cross-dock facility.

- Opportunistic cross-docking: This involves transferring products based on real-time demand or supply chain requirements, without pre-planning.

Cross-Docking Benefits

- Saving warehouse space: Products spend less time in a warehouse, so companies don’t need as much space to store them

- Fewer errors: Since products are handled less, there’s less risk of mistakes being made during the handling process.

- Ability to respond quickly: Cross-docking enables companies to react quickly to changes in customer demand, which helps them stay ahead of their competitors.

- More environmentally friendly: Cross docking helps to reduce transportation emissions and costs because it eliminates the need for multiple shipments.

- Faster delivery times: Cross-docking can speed up the delivery process since products are shipped directly from the supplier to the customer without being stored in a warehouse.

- Lower inventory costs: Since products spend less time in a warehouse, companies can reduce their inventory storage costs.

- Reduced handling costs: Cross-docking minimizes the need for product handling, which can reduce labor costs and the risk of damage to products.

- Improved product quality: Cross-docking can include product sorting and screening, which helps to identify any quality issues before products are shipped to customers.

- Enhanced supply chain efficiency: By streamlining the distribution process, cross-docking improves overall supply chain efficiency, reduces lead times, and improves customer satisfaction.

- Increased sustainability: Cross-docking can help reduce transportation emissions and costs by eliminating the need for multiple shipments.

Pre-Distribution vs. Post-Distribution Cross-Docking

Pre-distribution cross-docking happens before products are shipped to their final destinations. Products are sorted and organized by their destination in the cross-docking terminal. This means that when the products are shipped out, they are already grouped together by destination. Pre-distribution cross-docking can help speed up the shipping process and reduce inventory costs.

Post-distribution cross-docking happens after products arrive at the cross-docking terminal. Products are sorted and organized based on their final destination in the terminal. This means that the products may not be grouped together by destination until they arrive at the terminal, which can add time to the shipping process. Post-distribution cross-docking can be useful when dealing with unexpected changes in demand or supply.

Overall, pre-distribution cross-docking is more efficient and can be useful when dealing with predictable demand. Post-distribution cross-docking can be more flexible and can help companies adapt to unexpected changes in demand or supply.