In today’s warehouse management practices, the utilization of a warehouse management system (WMS) has become indispensable. While there are several small optimizations that can be implemented for long-term value, the overall management of warehouses is predominantly carried out through WMS software.

Warehouse management systems (WMS) are software applications that optimize warehouse operations and procedures. WMS enables you to assure the most efficient and cost-effective movement of products and commodities. It allows monitoring warehouse layout, inventory management, picking and packing goods, receiving and shipping, labour management, and reporting.

As a crucial component of logistics management systems, a WMS is specifically designed to efficiently manage, control, and optimize various warehouse processes. These processes encompass activities such as receiving and storing goods, as well as billing and generating reports.

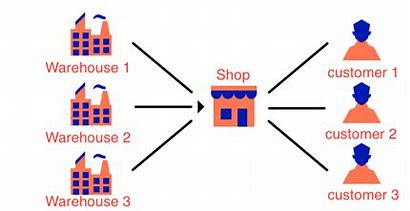

Multi-Warehouse Inventory Management

Multi-warehouse inventory management is a critical feature of a comprehensive warehouse management system (WMS) that enables businesses to efficiently manage inventory across multiple locations. It provides real-time visibility and control over stock levels, movements, and availability across all warehouses.

Multi-warehouse management software

Warehouse Management Systems: Key Processes, Features, and WMS Software Providers Compared

Warehouse Management Systems (WMS) are software solutions that streamline and optimize warehouse operations, including inventory management, order fulfillment, and overall warehouse efficiency. Let’s explore the key processes, features, and some notable WMS software providers.

1. Receiving:

Managing the receipt of goods into the warehouse, including inspection, labeling, and put away.

2. Inventory Management:

Monitoring and controlling stock levels, tracking inventory movements, and optimizing storage locations.

3. Order Management:

Processing customer orders, prioritizing orders, and facilitating efficient order picking and packing.

4. Shipping:

Preparing and coordinating outbound shipments, including packing, labeling, and carrier integration.Labor Management: Assigning and tracking tasks, optimizing labor utilization, and measuring performance.

5. Labor Management:

Assigning and tracking tasks, optimizing labor utilization, and measuring performance.

Top 8 Features Of Warehouse Management System (WMS)

1. inventory management

A robust warehouse management system should provide comprehensive inventory management capabilities. It includes real-time tracking of inventory levels, accurate stock counts, automated replenishment, and support for various inventory valuation methods.

2. order management

Efficient order management is a crucial feature of a WMS. It should enable order processing, order picking optimization, order prioritization, and order tracking. Additionally, it should support multiple order fulfillment methods, such as batch picking or wave picking.

3. Receiving and Putaway

The WMS should streamline the receiving process by automating data capture, generating receiving reports, and facilitating efficient putaway. It should assign optimal storage locations based on predefined rules or optimization algorithms.

4. Picking and Packing:

The WMS should optimize the picking process by providing picking instructions, suggesting optimal pick paths, and supporting different picking methods (e.g., zone picking, and batch picking). It should also enable efficient packing, including generating packing lists and printing shipping labels.

5. Warehouse Layout and Slotting:

A WMS should offer features for managing the layout and slotting of the warehouse. It includes defining storage zones, bin locations, and optimizing the placement of items based on factors such as velocity, size, and compatibility.

6. Labor Management:

The WMS should facilitate labor management by assigning tasks to warehouse personnel, tracking their performance, and providing productivity metrics. It should support labor optimization, such as workload balancing and suggesting optimal picking paths.

7. Reporting and Analytics:

A comprehensive WMS should provide reporting and analytics capabilities to monitor key performance indicators (KPIs). It should generate customizable reports and dashboards that offer insights into inventory levels, order fulfillment rates, picking accuracy, and other relevant metrics.

8. Integration with other Systems:

The WMS should seamlessly integrate with other systems within the supply chain ecosystem. This includes integration with enterprise resource planning (ERP) systems, transportation management systems (TMS), e-commerce platforms, and other third-party software or hardware solutions. The integration enables data flow and coordination between systems, improving overall operational efficiency.