Discover the benefits of implementing a Warehouse Management System (WMS) in your business.

Warehouse Management System, WMS

Warehouse Management System (WMS) is software designed to control and optimize warehouse operations. In today’s fast-paced and competitive business world, companies need efficient warehouse management systems to remain competitive. In this article, we will define what a warehouse management system is, discuss its role, benefits, different types of WMS, and highlight the difference between WMS and ERP systems.

What Is a Warehouse Management System?

A warehouse management system is a software solution that manages and controls warehouse operations for efficient inventory management, order fulfillment, and tracking of goods from receipt to shipment. The system ensures that items are stored in their proper locations, and the warehouse is organized in a way that allows for maximum efficiency and productivity.

One of the key features of a warehouse management system is its ability to track inventory levels in real-time. This means that warehouse managers can quickly and easily see how much inventory they have on hand, what items are selling quickly, and which items may need to be restocked soon. With this information, they can make informed decisions about when to order more inventory, how much to order, and where to store it in the warehouse.

Another important aspect of a warehouse management system is its ability to optimize the layout of the warehouse. By analyzing data on the movement of goods within the warehouse, the system can suggest changes to the layout that will improve efficiency and reduce the time it takes to pick and pack orders. This can include suggestions for where to store certain items, how to organize picking routes, and even which employees should be assigned to specific tasks.

In addition to these core features, many warehouse management systems also offer advanced functionality such as barcode scanning, automated data capture, and integration with other business systems such as ERP and CRM. These features can help to further streamline warehouse operations and improve overall efficiency.

Overall, a warehouse management system is an essential tool for any business that relies on efficient Inventory Management and order fulfillment. By providing real-time visibility into inventory levels and optimizing warehouse operations, these systems can help businesses to reduce costs, improve customer satisfaction, and stay competitive in today’s fast-paced marketplace.

What Does a Warehouse Management System Do?

A warehouse management system (WMS) is a sophisticated software solution that is designed to streamline the operations of a warehouse. It performs a range of tasks, including tracking inventory levels, managing order picking, packing, and shipping, and optimizing warehouse space. With a WMS, warehouse managers can automate various operations such as receiving, put-away, picking, packing, and shipping, thereby reducing manual input and inefficiencies.

One of the key benefits of a WMS is that it enables warehouse managers to track the movement of goods from one location to another. This helps minimize errors and improve delivery times, as managers can quickly identify where products are located within the warehouse and how long they have been there. By having this level of visibility, warehouse managers can optimize their operations and ensure that products are delivered to customers on time.

In addition to tracking inventory levels and managing order processing, a WMS can also help optimize warehouse space. By analyzing the layout of the warehouse and the movement of goods, the software can recommend changes to the layout that will improve the efficiency of the warehouse. For example, the software may recommend that certain products be stored in a different location within the warehouse to reduce the time it takes to pick and pack orders.

Another benefit of a WMS is that it can help warehouse managers reduce labor costs. By automating various tasks, such as order picking and packing, warehouse managers can reduce the number of employees needed to operate the warehouse. This not only saves money, but also reduces the risk of errors and improves the overall efficiency of the warehouse.

Overall, a warehouse management system is an essential tool for any business that operates a warehouse. With its ability to track inventory levels, manage order processing, optimize warehouse space, and reduce labor costs, a WMS can help businesses improve their bottom line and deliver better service to their customers.Warehouse management systems have become an essential tool for businesses that operate warehouses.

They help to streamline operations, reduce errors, and improve overall efficiency. One of the most popular examples of a warehouse management system is the “SAP Extended Warehouse Management” software. This software is widely used across industries and is known for its comprehensive features and capabilities.One of the key benefits of the SAP Extended Warehouse Management software is its ability to automate all warehouse operations.

This means that businesses can reduce the need for manual labor and can rely on the software to handle tasks such as receiving, put-away, picking, packing, and shipping. This automation not only saves time but also reduces errors, which can be costly in a warehouse environment.Another important feature of the SAP Extended Warehouse Management software is its real-time visibility and tracking of goods.

This allows businesses to monitor inventory levels, track the movement of goods, and ensure that orders are fulfilled in a timely manner. The software also supports mobile devices, which means that workers can access information and perform tasks from anywhere in the warehouse.

In addition to these features, the SAP Extended Warehouse Management software also integrates with other enterprise systems such as ERP. This integration allows for seamless communication between different departments and systems, which can further improve efficiency and reduce errors.

Overall, the SAP Extended Warehouse Management software is an excellent example of a warehouse management system. Its comprehensive features and capabilities make it a popular choice for businesses of all sizes and industries. By automating warehouse operations, providing real-time visibility and tracking of goods, and integrating with other enterprise systems, this software helps businesses to improve their warehouse operations and stay competitive in today’s fast-paced business environment.

What Is the Role of a Warehouse Management System?

The primary role of a warehouse management system is to provide real-time visibility and control of warehouse operations, enabling companies to manage their inventory efficiently, control costs, and reduce errors. It also helps optimize warehouse space utilization, increases productivity, and improves customer satisfaction through faster and more accurate order fulfillment.

With the help of a warehouse management system, companies can track inventory levels, monitor stock movements, and manage the receipt and dispatch of goods. The system uses barcode scanning and RFID technology to identify and track products, making it easier to locate specific items within the warehouse.

Additionally, a warehouse management system can help companies streamline their supply chain operations by providing real-time data on inventory levels, order status, and shipping information. This allows companies to make informed decisions about production and distribution, reducing the risk of stockouts and overstocking.

Another important role of a warehouse management system is to improve the accuracy and speed of order fulfillment. By automating the picking and packing process, the system can reduce the time it takes to process orders and minimize the risk of errors. This can lead to improved customer satisfaction and increased sales.

Furthermore, a warehouse management system can help companies reduce costs by optimizing warehouse space utilization. The system can identify areas of the warehouse that are underutilized and suggest ways to improve storage efficiency. This can lead to reduced storage costs and improved profitability.

In summary, a warehouse management system plays a critical role in modern supply chain operations. It provides real-time visibility and control of warehouse operations, improves inventory management, increases productivity, and enhances customer satisfaction. With the help of a warehouse management system, companies can optimize their supply chain operations and achieve greater efficiency and profitability.

Why Is a Warehouse Management System Needed?

In today’s competitive business environment, companies must streamline their warehouse operations to remain profitable and stay competitive. A warehouse management system is needed to achieve this goal by automating manual processes, optimizing space utilization, reducing errors, and providing visibility and control of inventory movements.

Benefits of a Warehouse Management System

Implementing a warehouse management system has several benefits, including:

- Reduced labor costs and increased productivity: Businesses can reduce labor costs and increase productivity by automating manual processes, including tracking inventory and order fulfillment.

- Improved inventory accuracy: With real-time data, businesses can track inventories, determine stock levels, and avoid costly stockouts or overstocks.

- Optimized space utilization: A WMS maximizes warehouse space utilization by defining storage locations and managing inventory placement to ensure efficient use of space.

- Enhanced customer satisfaction: A WMS’s real-time inventory and order tracking features allow for faster and more accurate order fulfillment, improving customer satisfaction.

- Improved supply chain efficiency: Integration with other systems such as ERP improves efficiency across the entire supply chain.

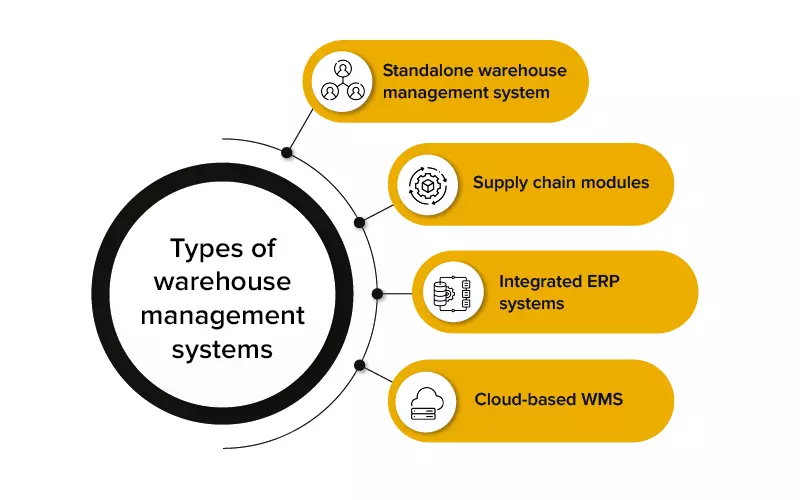

Types of Warehouse Management Systems

There are different types of warehouse management systems available, including:

- Standalone WMS: A standalone WMS is a software solution that only manages warehouse operations, providing real-time visibility and control over inventory and warehouse processes.

- Integrated WMS: An integrated WMS is a software solution that manages inventory, warehouse operations, and other supply chain processes, including transportation management.

- Cloud-based WMS: A cloud-based WMS is a software solution that operates in the cloud, allowing businesses to access the system from anywhere and at any time, usually on a subscription basis.

Features of Warehouse Management Systems

A WMS typically includes the following features:

- Inventory management

- Barcode scanning

- Picking optimization

- Slotting optimization

- Real-time data tracking and reporting

- Task prioritization

- Receiving and put-away optimization

- Order management and fulfillment

Is Excel a Warehouse Management System?

Excel is a spreadsheet program and is not a warehouse management system. While it is possible to track inventory levels and manage other warehouse operations using Excel, it is not an efficient and scalable solution for warehouse operations.

Difference Between WMS and ERP System

While both WMS and ERP systems manage business operations, their scope and focus differ. A WMS is specifically designed to manage warehouse operations, including inventory tracking, order fulfillment, and warehouse space optimization. An ERP system, on the other hand, helps to manage business operations, including financial management, human resources management, and supply chain management. While some ERP systems have warehouse management features, they are not as robust as standalone WMS systems.

Conclusion

A warehouse management system is an essential tool for any company that manages inventory. It provides real-time visibility and control over warehouse operations, reduces labor costs, optimizes space utilization, improves inventory accuracy, and enhances customer satisfaction. There are different types of WMS available, and businesses should choose a system that meets their unique needs. By investing in a WMS, businesses can achieve significant efficiencies and maintain a competitive edge in today’s market.